“Since the completion of the Human Genome Project, technological improvements and automation have increased speed and lowered costs to the point where individual genes can be sequenced routinely… and an entire genome can be sequenced for just a few thousand dollars.”

– National Human Genome Research Institute (NHGRI) Fact Sheet – August 2020

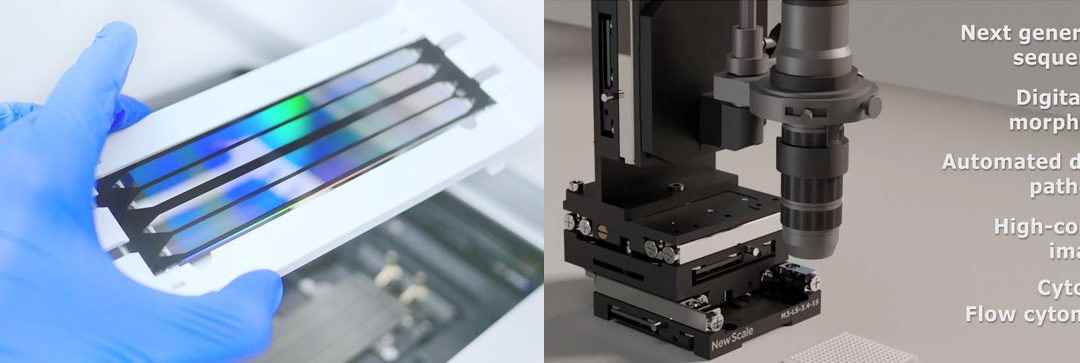

Building on the Human Genome Project, companies are racing ahead with developing instruments for DNA sequencing. The newest techniques and instruments for NGS (Next-Generation Sequencing) are focused on two key trends: increasing throughput and reducing cost.

High throughput sequencing improves statistical power from larger sample sizes and reveals the full breadth of variation in whole genome sequencing [1]. Lower cost sequencing has potential to serve as the foundation for new approaches to screening, diagnosis and risk prediction in clinical practice [2] as well as aiding in genomic research.

Next-generation methods for genome sequencing include massively parallel signature sequencing, polony sequencing, 454 sequencing, Illumina technology, ion torrent technology, SOLiD DNA sequencing technology, and DNA nanoball sequencing [3].

To achieve the goals of higher throughput and lower costs, NGS instrument developers are using:

- smaller samples

- parallel sequencing

- more automation

M3 Modules for miniaturization and control of photonics subsystems

Achieving these goals requires designers to master miniaturization and distributed control of the photonics subsystems used in DNA sequencing instruments. These optical subsystems include light sources and imaging sensors. They require sub-micrometer adjustments to individually tune and actively align photonic components.

For example, the instrument designer must:

Optimize laser spot size, wavelength and power in more tightly-spaced flow cells, so that maximum energy falls within a defined volume and location in the lane, channel or nanowell.

Focus imaging optics to collect light in a precise volume, defined by field-of-view (FOV) and depth-of-focus (DOF), while at the same time reducing instrument size.

Prevent and compensate for thermal drift, both in the instrument alignment and in the power and wavelength of light sources.

Limit outgassing to avoid contamination of optics directing high-energy laser sources.

Miniaturize mechanical components to match the spacing of increasingly smaller, close-packed samples in the flow cells.

Reduce the number of electrical connections and cables and the required bandwidth of communications between each subsystem and the instrument computer.

Simplify and standardize the digital commands to each subsystem to accelerate integration, calibration, testing and deployment.

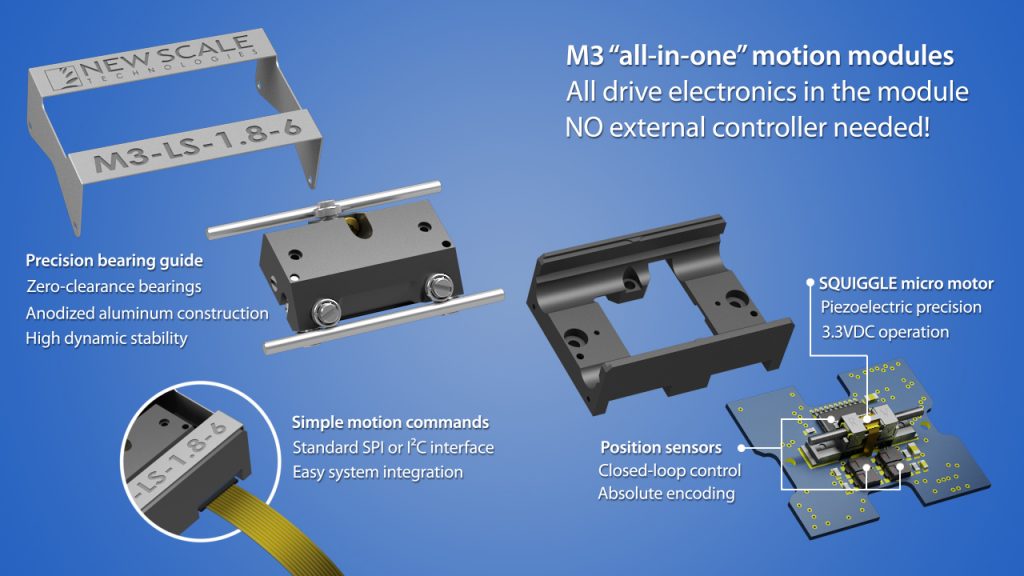

These challenges are addressed by next-gen piezoelectric “micro-mechatronic motion” (M3) modules from New Scale Technologies. These components are small, precise and smart (with embedded controllers and firmware). They are being integrated into NGS instruments for research and clinical use.

Here’s how M3 modules address the key challenges outlined above.

Optimizing spot size in the flow cell

A focus module or microstage is used to move a focusing lens. With a position resolution of 0.5 microns, an M3 focus module maintains a precise spot size with high repeatability and accuracy.

An M3 microstage can not only move a focusing lens, but also provide linear motion to center the spot in the desired location with a resolution of 0.5 microns and high repeatability and accuracy.

M3 rotary stages offer additional beam positioning options, again with a resolution of 0.5 microns and high repeatability and accuracy.

Preventing and compensating for thermal drift

The spot from the light source will move or drift with internal heating of the instrument during normal operation, or changes in the external ambient temperature.

An M3 module is a closed-loop motion system that responds to and compensates for this drift, to automatically maintain optimal instrument performance. Each module has on-board temperature sensing and memory that enables in-situ testing and calibration of each photonics subsystem.

Additionally, M3 modules avoid contribution to thermal drift themselves in two ways.

(1) The self-locking design uses power only when moving. No power is drawn, and no heat is generated, for the M3 module to hold a fixed position.

(2) They use low power from a < 5VDC supply when moving. For example:

- An M3-F focus module (3.1 to 2.5 VDC input) uses less than 1W when moving at 5 mm/s with a 5g load.

- An M3-LS-U2 micro stage (5VDC input) uses 2.3W peak at its maximum speed (35 mm/s) and force (0.2N).

- NGS instruments are typically low duty cycle and do not require maximum speed or force, resulting in even lower average power use.

Limiting outgassing

M3 modules are based on patented piezoelectric motors. These SQUIGGLE® and UTAF™ piezoelectric motors operate with no lubricants, resulting in low outgassing. They deliver direct linear or rotary movement with no gears or cams. They also offer greater power efficiency, higher reliability, and ten times better precision than electromagnetic motors.

Miniaturizing all components

M3 modules enable NGS instrument designers to embed precision motion in the smallest volume inside the DNA sequencing instrument. This is essential to fit the motion components into the space needed for parallel sequencing.

Each M3 module combines a miniature piezoelectric motor, precision mechanical elements, position sensors, and motion control functions in a compact device. This not only ensures smallest system size, but also speeds the design process.

To avoid reserving needless space and complexity for motion components, NGS instrument designers should consider M3 modules at the beginning of the design process.

An M3 module works as a simple I2C or SPI slave. This eliminates bulky electronics, cables and connectors, which can be many times larger than the discrete moving stage. The modules combine part functions to further reduce space used, for example, a single printed circuit board holds the motor, driver, sensor and microprocessor.

Leveraging expertise in micro-mechatronics

Micro-mechatronics is a highly specialized engineering discipline. An M3 module represents thousands of hours and millions of dollars in mechatronic system development investment by micro mechatronic experts. As a single part, it simplifies motion design and integration tasks to one mechanical interface, one electrical connector for DC power and digital bus, and one simplified software interface. It requires no matching of the motor to the controller, nor even control engineering skills such as tuning a PID control loop.

M3 modules allows NGS instrument designers to focus on their core competencies and bring new DNA sequencing instruments to market faster.

References

[1] https://www.illumina.com/systems/sequencing-platforms/novaseq.html

[2] https://www.ncbi.nlm.nih.gov/pmc/articles/PMC3818164/ Reflections on the Cost of “Low-Cost” Whole Genome Sequencing: Framing the Health Policy Debate, T. Caulfield et. al., PLoS Biology, 2013

[3] https://www.sciencedirect.com/science/article/pii/B9780444636676000079 Next-Generation Sequencing Methods; T. Rajesh, M. Jaya; Current Developments in BIoetechnology and Bioengineering – Functional Genomics and Metabolic Engineering, 2017

Technical Review By

Stefan Friedrich

Marketing Manager